Seeing the Whole Picture

Many Reliability Improvement programmes focus on eliminating defects after they have

happened. They are only looking at the tip of the iceberg.

Our Reliability Iceberg process is based on the simple premise that for every loss of Plant Integrity, Production Efficiency or Cost Performance there is an underlying and often less obvious cause.

The Iceberg process transforms the focus of Reliability Management, by enabling you to effectively monitor and manage the underlying causes before the critical failures happen.

The process establishes and implements the strategies and performance indicators required to manage each of the key causal factors of poor reliability performance, which can be attributed to plant design, construction, operation, maintenance and the related human and organisational factors.

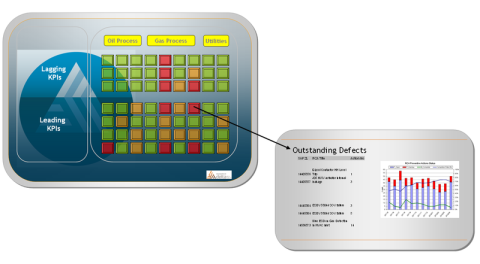

An intuitive dashboard tool highlights the status of the key reliability indicators for each critical plant system and the relationship between the Leading and Lagging Indicators of reliability performance. Drilldown features enable you to analyse the supporting data to identify and eliminate the underlying causes of tomorrow’s failures.

The Reliability Iceberg provides both a strategic roadmap and a tactical dashboard to achieving Operational Reliability excellence, enabling you to identify and build on your organisation's current strengths and weaknesses.

See the whole picture with the Reliability Iceberg and eliminate the causes of tomorrow's business losses today.

To find out more about how we can help your organisation melt the Reliability Iceberg:

Please visit our Capability and Home pages,

or contact us directly.